In the current era of electric vehicles, there is a critical need for efficient and high-performance power electronic devices. Traction inverters are a key component of electric vehicles (EVs) as they are responsible for converting the battery's direct current into AC power to drive the electric motor.

Recently, a breakthrough substance called silicon carbide (SiC) has emerged that has completely changed the way these inverters work. This paper explores the advantages of silicon-based traction inverters over silicon-based traction inverters that have revolutionized the efficiency, power density, and sustainability of electric vehicles.

SiC in traction inverters

Silicon Carbide is a compound composed of silicon and carbon, renowned for its exceptional characteristics. The distinctive attributes of this material encompass elevated thermal conductivity, superior breakdown voltage, and exceptional chemical resistance. SiC, unlike conventional silicon-based semiconductors, can function at elevated temperatures and voltages, rendering it a very suitable option for power electronics applications.

Traction inverters serve as the key component of an electric vehicle’s powertrain. Historically, inverters have relied on silicon-based semiconductors as their primary component. Nevertheless, the constraints of silicon, particularly under demanding conditions with high power and elevated temperatures, have prompted researchers and engineers to explore other materials. SiC provides a revolutionary answer in this context.

The application of SiC-based power devices in traction inverters brings several benefits, including:

● Higher efficiency: SiC-based inverters provide higher efficiency in comparison to silicon counterparts. The heightened efficiency leads to reduced power loss during the conversion procedure, hence improving the overall performance and driving distance of electric vehicles. Moreover, SiC devices have lower on-state resistance (Rds(on)) and switching losses compared to silicon devices. This results in higher overall efficiency in power conversion processes within traction inverters. The reduced energy loss during power conversion contributes to improved vehicle efficiency and longer driving ranges for electric vehicles. SiC-based inverters can achieve efficiencies above 98%, surpassing the capabilities of silicon inverters.

● Higher power density: The improved thermal conductivity of SiC enables higher power density in traction inverters. SiC-based inverters can manage higher power levels within a compact and lightweight design, thereby supporting the current trend of minimizing the dimensions and mass of electric vehicle components. This is crucial for electric vehicles, where reducing the size and weight of power electronics components is a key goal for enhancing overall vehicle performance and efficiency.

● Better thermal management: SiC’s capacity to endure elevated temperatures enhances the thermal efficiency of traction inverters. This not only improves the longevity of the components but also enables more assertive and effective power management tactics.

● Higher switching frequencies: SiC devices can turn on and off at significantly greater frequencies in comparison to conventional silicon devices. The inverter’s fast switching capabilities minimize the energy losses during switching, leading to enhanced overall efficiency and smoother operation.

● Reduced cooling requirements: Traction inverters made of silicon carbide (SiC) need less cooling than inverters made of silicon because of SiC’s better thermal properties. Electric vehicles can reduce their overall weight thanks to cooling systems that can run at higher temperatures without compromising performance. These systems are smaller and lighter.

● Higher operating voltage: In comparison to silicon devices, SiC devices are capable of withstanding higher voltage levels. Because of this quality, traction inverters with higher voltage capabilities can be designed, which gives more leeway in the system’s overall design and could lead to a reduction in the number of powertrain components required.

Below are some of the commercial SIC-based solutions from leading semiconductor manufacturers that address the needs of automotive traction inverters and other demanding power applications.

STMicroelectronics

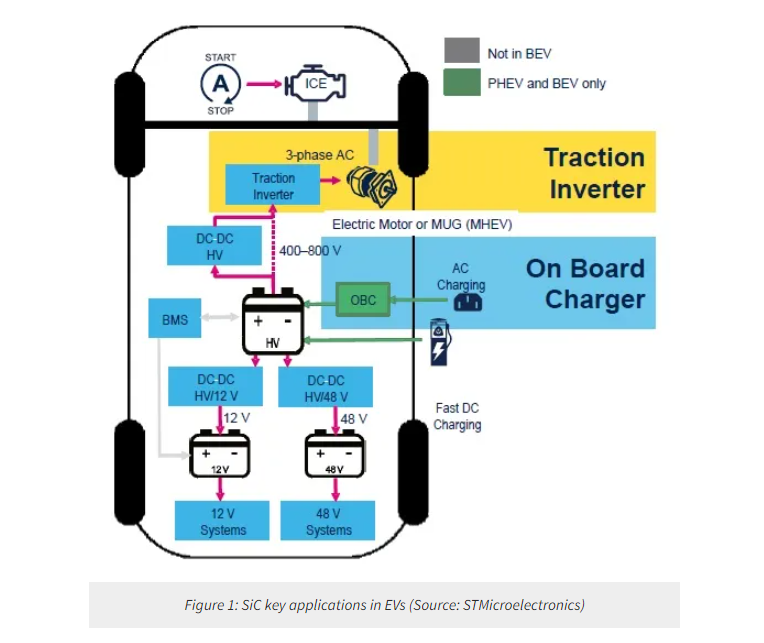

As shown in Figure 1, two SiC key applications in electric vehicles (EVs) are the traction inverter and the onboard charger (OBC). The traction inverter includes the high-power inverter stage that is responsible for driving the traction motor of the vehicle (typically, a 3-phase AC motor).

In this application, by replacing the conventional Si IGBTs and diodes with SiC MOSFETs and SiC power MOSFETs, results in higher efficiency, reduced footprint, and less cooling efforts. A 3-phase inverter based on SiC MOSFETs shall be bidirectional, feeding the electric motor when driving the wheels, and streaming energy back on the HV Bus when braking the vehicle. ST’s SiC MOSFETs, available in 650V, 750V, and 1,200V, can meet the requirements of both 400V and 700-800V EV buses.

ST’s ACEPACK power modules are designed for power applications that range from a few to hundreds of kilowatts. These modules are offered in several configurations that utilize SiC MOSFET or IGBT-diode switch technologies.

Additionally, the ACEPACK DRIVE is a compact and liquid-cooled series of sixpack SiC modules that are specifically designed for optimal performance in hybrid and electric car traction inverters. They ensure superior Rds(on) values, minimal switching and conduction energies, and exceptional performance in synchronous rectification operations. The module guarantees enhanced system efficiency, particularly during regenerative braking, when compared to conventional market alternatives. The ACEPACK DRIVE series enhances the fuel efficiency of electric vehicles and enables the use of smaller battery packs. The ACEPACK DRIVE has a voltage rating ranging from 750 V to 1200 V.

Infineon

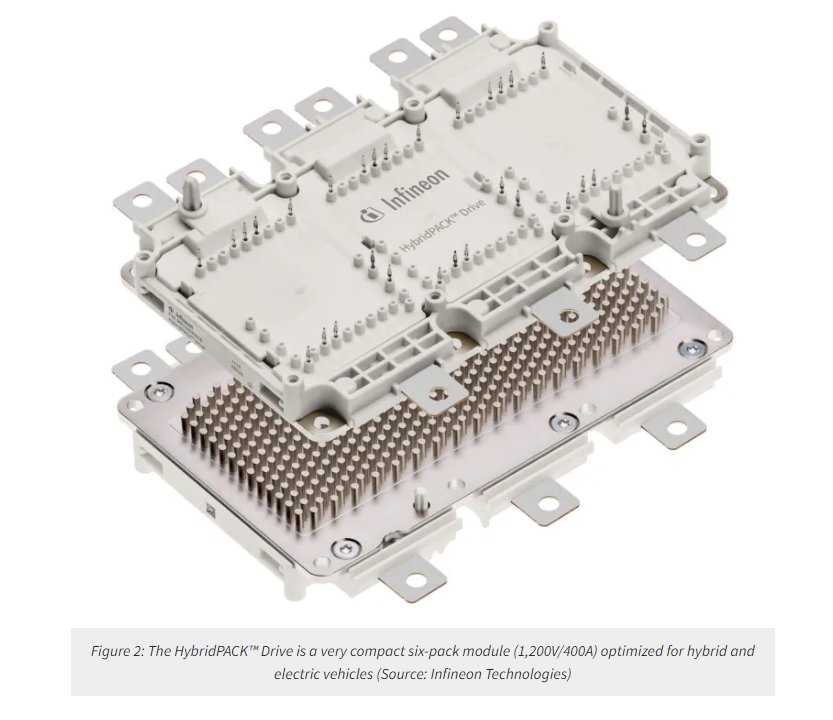

Infineon Technologies offers a wide portfolio of SiC MOSFETs and power modules suitable for electric and hybrid vehicles’ traction inverters. Among these products is the HybridPACK™ Drive, a compact power module designed specifically for the traction applications of hybrid and electric vehicles. It offers a flexible power range of 100kW to 250kW, suitable for vehicles in the 750 V and 1,200 V classes.

The design of the product (Figure 2) enables customers to adjust performance levels by utilizing thermal stacks and other chipsets, based on their preferred balance between cost and performance, while still preserving the same module size. The HybridPACK™ Drive is Infineon’s power module that has achieved significant market success, with nearly three million units supplied for over 20 electric car platforms.

Infineon unveiled the latest iteration of CoolSiC™ in 2021, which utilizes Infineon’s silicon carbide trench MOSFET design. The Trench structure allows for a greater cell density compared to planar structures, resulting in the best-in-class figure of merit. Consequently, trench MOSFETs can function at reduced gate-oxide field strengths, leading to enhanced dependability.

Onsemi

onsemi’s EliteSiC module solutions serve as the basis for designing traction inverters, ensuring automotive goods possess both high power and dependability. The EliteSiC power modules for traction inverters include options for bare die solutions, gel-encapsulated case modules, and transfer molded modules, all of which include complete SiC MOSFETs. The EliteSiC product line provides superior performance, enhanced efficiency, and more power density compared to IGBT solutions. These advantages are achieved with similar and very compatible packaging choices.

SiC Modules comprise SiC MOSFETs and SiC diodes. The boost modules are employed in the direct current to direct current stages of solar inverters. These modules utilize Silicon Carbide (SiC) Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) and SiC diodes with a voltage rating of 1,200 volts. A Silicon Carbide (SiC) Module is a power module that utilizes Silicon Carbide semiconductors as its switch. The primary objective of a SiC power module is to enhance system efficiency by utilizing switches to convert electrical power.

The primary function of SiC Modules is to transform electrical power. Silicon Carbide offers an advantage over silicon because, with less resistance to moving away from the source (due to increased efficiency), SiC devices can operate at a higher switching frequency. A SiC-based system is also more compact and lightweight than a silicon solution, allowing for smaller designs. Therefore, SiC devices are the ideal solution for situations where you want to increase efficiency and improve your thermal management.

Onsemi’s EliteSiC power modules are available in the Single-Side Direct Cooling, 6-Pack, 900V version, and in the Single-Side Cooling, Half Bridge, 1,200V version.

Conclusion

In terms of electric mobility, SiC based traction inverters are a huge step forward. Silicon carbide can promote the widespread use of electric vehicles because it has many advantages, such as enhanced thermal performance, higher efficiency and higher power density. Despite the obstacles that remain, continued advances in SiC technology bode well for a bright future for electrification in transportation and other areas.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.